SCHONEWEG CANDLE FILTER SYSTEMS

FOR YOUR APPLICATIONS & REQUIREMENTS

STANDARD-LINE

EXTRA-LINE

"WHERE & WHAT"? INDUSTRIES & APPLICATIONS FOR CANDLE FILTER SYSTEMS

EXAMPLES of the USE of SCHONEWEG CANDLE FILTER SYSTEMS

"WHICH MATERIAL"? SUITABILITY OF MATERIALS FOR FILTER SYSTEMS

INFORMATION on RESISTANCES & PROPERTIES OF STAINLESS STEELS & PLASTICS that can help you meet your SPECIFIC REQUIREMENTS.

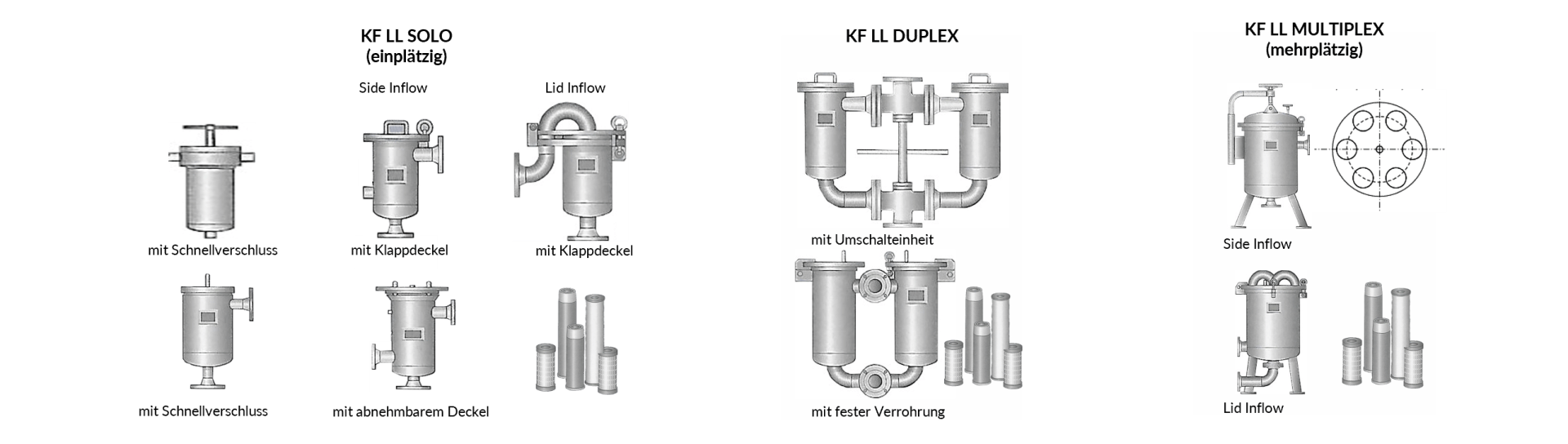

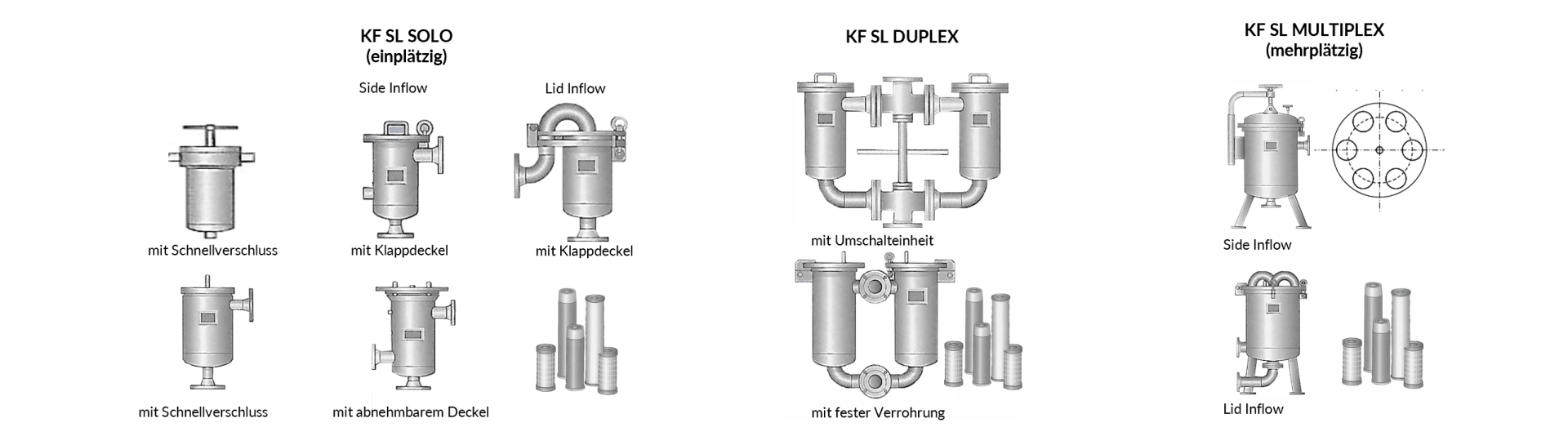

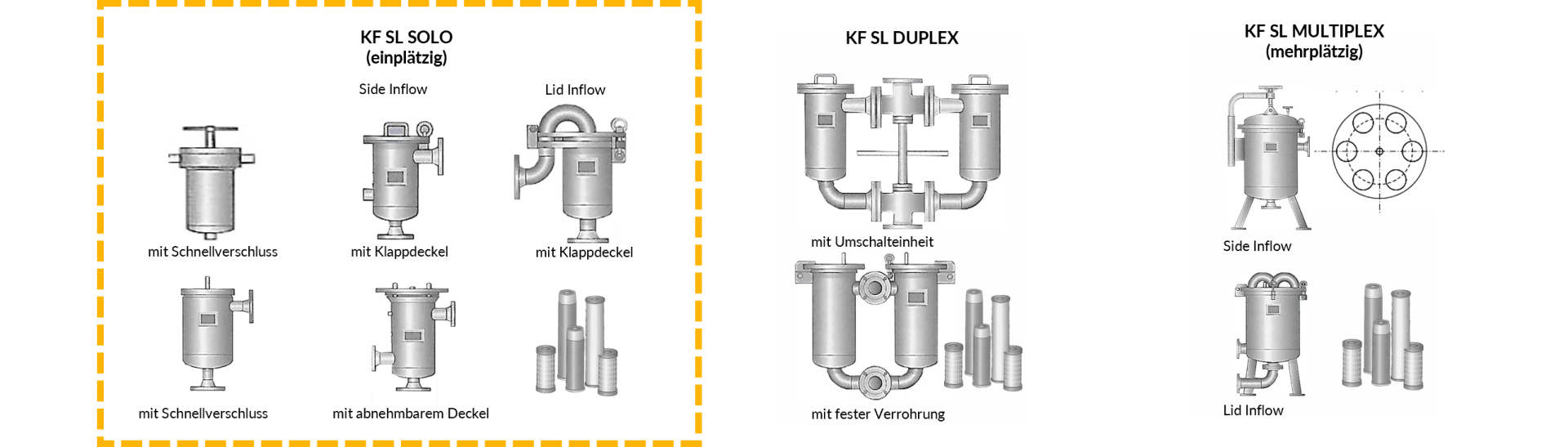

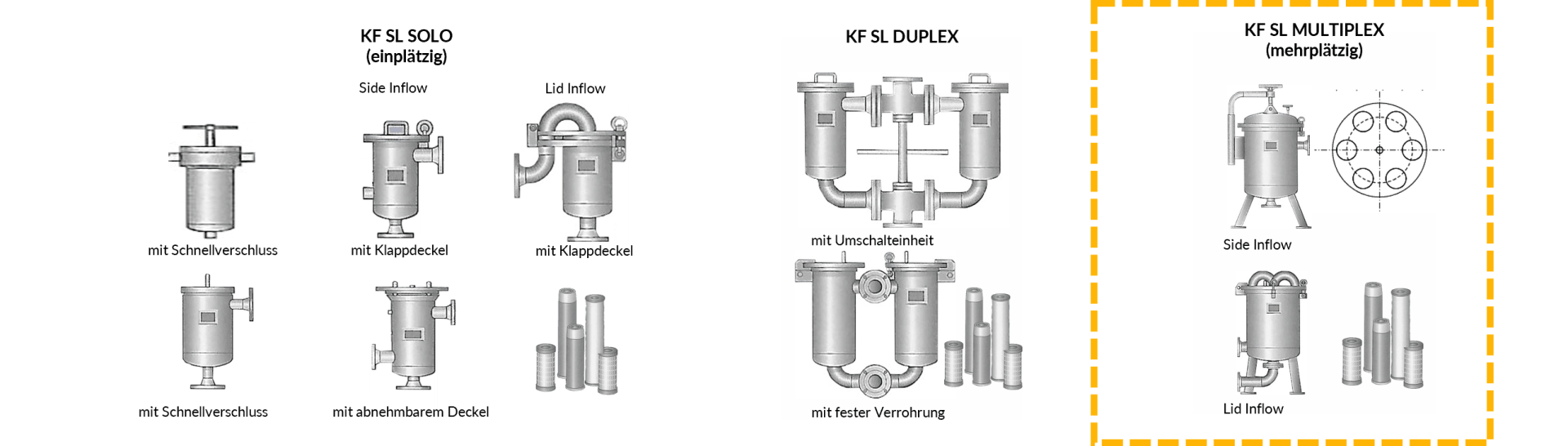

QUICK-VIEW: 3 EXPANSION LEVELS for CANDLE FILTER SYSTEMS

(FOR A QUICK OVERVIEW PLEASE UNFOLD THE MAPS)

CANDLE FILTER SYSTEMS of LIGHT-LINE

SPECIFICATIONS & VARIANTS

CANDLE FILTER SYSTEMS of STANDARD-LINE

SPECIFICATIONS & VARIANTS

CANDLE FILTER SYSTEMS of EXTRA-LINE

ADDITIONAL OPTIONS FOR THE STANDARD LINE

suitable filter candles (wound candles, activated carbon candles, meltblown, membrane filter candles and filter candles made of stainless steel)

- in standard or individual sizes,

- all subtleties / permeabilities,

- in many designs and

- with additional EXTRAs (e.g. FDA / EC conformity)

is here:

QUOTE REQUEST & CHECKLIST FOR FILTER systems

YOU ALREADY HAVE AN IDEA OF YOUR NEEDS - CAPTURE & SEND US YOUR SPECIFICATIONS

Let us know - optionally via our

checklist and / or by sending your documents (You have the option to upload files in the "DRAWINGS, SKETCHES, PRODUCT DESCRIPTIONS, ETC."

Please let us know the requirements of your application or project so that we have information about your needs. We will evaluate this information and get back to you.